Stamps

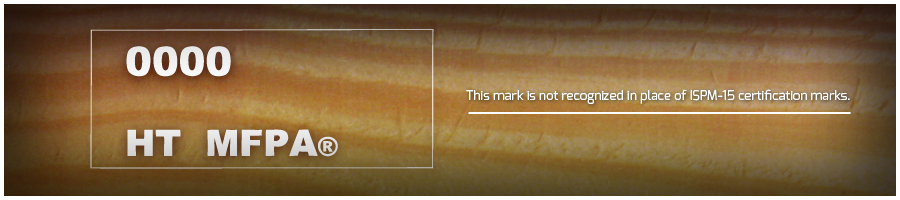

An internationally recognized mark must be applied to all complying WPM. This quality mark or stamp is comprised of the two letter ISO country code, the certifying agency logo, the facility identification (typically a number), the IPPC symbol, and the letters HT (heat treat) or MB (methyl bromide). There may also be a DUN or DUNNAGE designation included in the mark to identify dunnage material.

There are three types of stamps used in conjunction with ISPM-15:

Heat Treated (HT) Lumber Grade Stamp

This mark indicates that individual solid wood raw material has met the minimum core temperature of 56 C for 30 minutes.

The mark serves in establishing a chain of custody between the site that treated the raw materials and the site that will certify finished WPM as being in compliance with ISPM-15 guidelines.

Finished Product HT Quality Mark

This mark identifies assembled WPM (pallets, boxes, crates, etc.) as being heat-treated and debarked in compliance with ISPM-15. This mark shall be visible when the wood packaging is in use and applied legibly a minimum of two times on opposite faces by wood packaging manufacturers.

Where various components are integrated into a unit of wood packaging material, the resultant composite unit should be considered as a single unit for marking purposes. On a composite unit of wood packaging material made of both treated wood and processed wood material (where the processed component does not require treatment), it may be appropriate for the mark to appear on the processed wood material components to ensure that the mark is in a visible location and is of a sufficient size.

HT Quality Dunnage Mark

Dunnage is defined as WPM used to secure or support a commodity but which does not remain associated with the commodity. This mark identifies wood dunnage (blocking, bracing, chocking, etc.) as being heat-treated and debarked in compliance with ISPM-15. Generally, the mark should be applied legibly every 24 inches. The quality dunnage marks may only be obtained through an accredited inspection agency.

Marking the dunnage every 24 inches may be necessary since treated wood for use as dunnage may not be cut to final length until loading of a conveyance takes place. It is important that shippers ensure that all dunnage used to secure or support commodities is treated and displays the mark, and that the marks are clear and legible. Small pieces of wood that do not include all the required elements of the mark should not be used for dunnage.